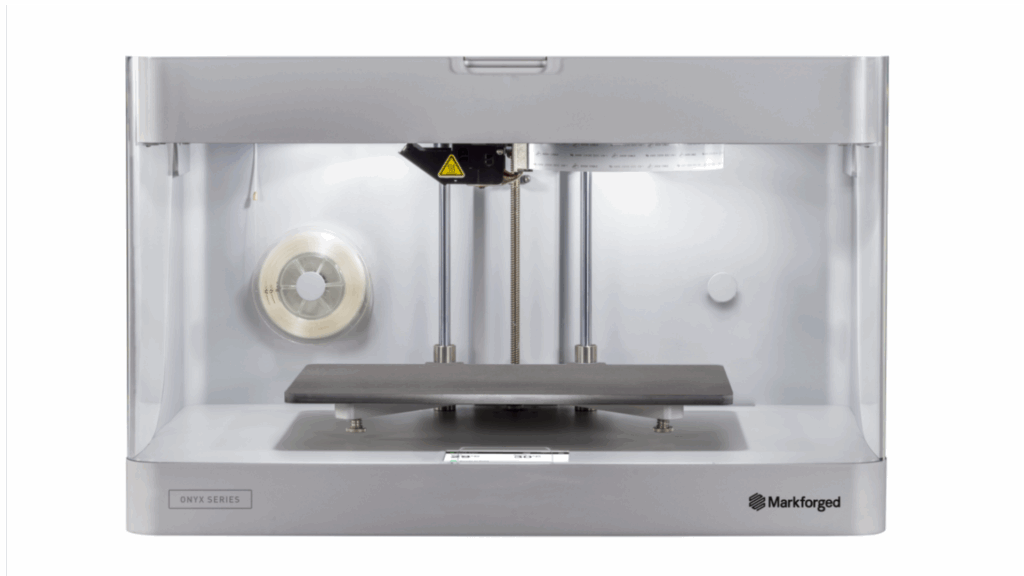

Industrial 3D printer for the production of robust components with continuous fiber reinforcement

The FX10 is Markforged’s latest industrial 3D printer – designed for the serial production of strong, precise components directly in-house. With its robust construction, a closed print chamber, automated calibration, and two interchangeable print heads, the FX10 delivers the highest process reliability – day after day, shift after shift.

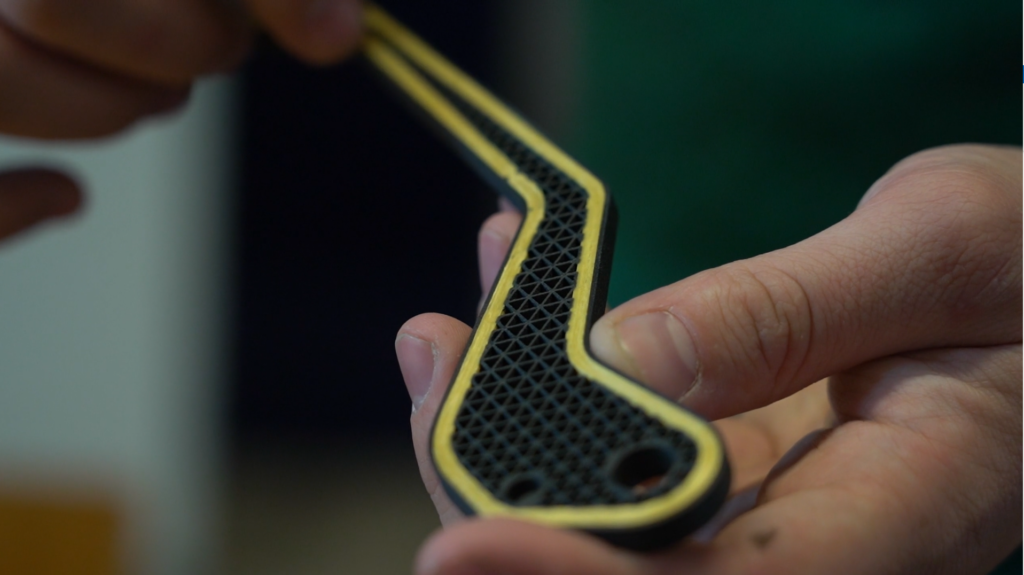

Thanks to Markforged’s proprietary continuous fiber technology, components can be reinforced with carbon, Kevlar, or glass fibers, achieving strength comparable to aluminum while being lighter. Ideal for equipment, grippers, fixtures, and spare parts that must withstand harsh industrial environments.

The system processes Onyx (a nylon-based material with microcarbon fiber) as well as other high-performance materials such as Onyx FR or Smooth TPU 95A. The modular design also allows for quick switching between composite and metal 3D printing, as the FX10 is also compatible with the metal print head. This makes it particularly flexible – without the need for a second machine.

The FX10 is controlled by the intuitive Eiger software, which can be operated cloud-based or locally. The integrated sensors and automatic laser measurement ensure consistent quality and reduce manual intervention to a minimum.

Key Features:

Build volume: 375 x 300 x 300 mm

Print materials: Onyx, Onyx FR, Onyx ESD, TPU, continuous fiber

Two interchangeable print heads (composite and optionally metal)

Automatic calibration & laser measurement

Integration into existing manufacturing processes possible

The FX10 is designed for companies that not only want to test additive manufacturing, but also want to use it productively and cost-effectively – today and in the future.